Extra care must be taken for certain items during storage and transit to preserve their integrity and quality. Cold chain management is useful in this situation. A crucial branch of supply chain management known as “cold chain management” is concerned with handling temperature-sensitive products throughout storage and transit, ensuring they are maintained within predetermined temperature ranges from manufacturing to delivery.

In this blog we will discuss the idea of cold chain management, its significance, and the Types of Supply Chain Management where it is essential. Also, we explore the significance of Supply Chain Management Certification.

Types of Supply Chain Management

It’s crucial to comprehend the different kinds of supply chain management before diving into cold chain management:

- Traditional Supply Chain Management: Product and material flow is managed in a traditional supply chain by suppliers, manufacturers, distributors, retailers, and consumers. Typically, it focuses on common supply chain procedures like distribution, manufacturing, inventory control, and procurement.

- Lean Supply Chain Management: The goal of lean supply chain management is to minimise waste and inefficiencies in the supply chain while preserving product quality and customer happiness. It focuses on streamlining procedures, eliminating extra inventory, and cutting lead times.

- Agile Supply Chain Management: Agile supply chain management is intended to swiftly adjust to market changes, supply, or demand. It emphasises adaptability, reactivity, and the capacity to quickly change course to satisfy client demands.

- Green Supply Chain Management: Sustainability concepts are incorporated into supply chain procedures via green supply chain management. It aims to lessen the negative effects of supply chain operations on the environment by encouraging eco-friendly packaging, cutting emissions, and preserving resources.

- Cold Chain Management: This blog’s topic, cold chain management, focuses on goods that need temperature control through the supply chain. It guarantees the safety and quality preservation of goods sensitive to temperature, including food, medications, vaccines, and biologics.

- The Significance of Cold Chain Management: Cold chain management is crucial for sectors that deal with perishable and temperature-sensitive commodities. They are important for the following main reasons:

- Product Quality and Safety: Keeping items at the proper temperature throughout storage and transit is essential to preserve their effectiveness, safety, and quality. Product deterioration or spoiling may occur from any departure from the recommended temperature range.

- Regulatory Compliance: Stringent rules govern temperature-sensitive product storage and transportation in several industries, including the pharmaceutical and healthcare sectors. Adherence to these standards is crucial to avoid legal and financial consequences.

- Consumer Confidence: Cold chain management is crucial to establishing and maintaining customer trust. Customers trust brands more when they know that goods like vaccinations and fresh vegetables have been treated carefully.

- Cost Efficiency: Effective cold chain management helps minimise waste and product losses, which in turn can save operating costs. Guaranteeing that goods are delivered and sold within their shelf life also enhances inventory management.

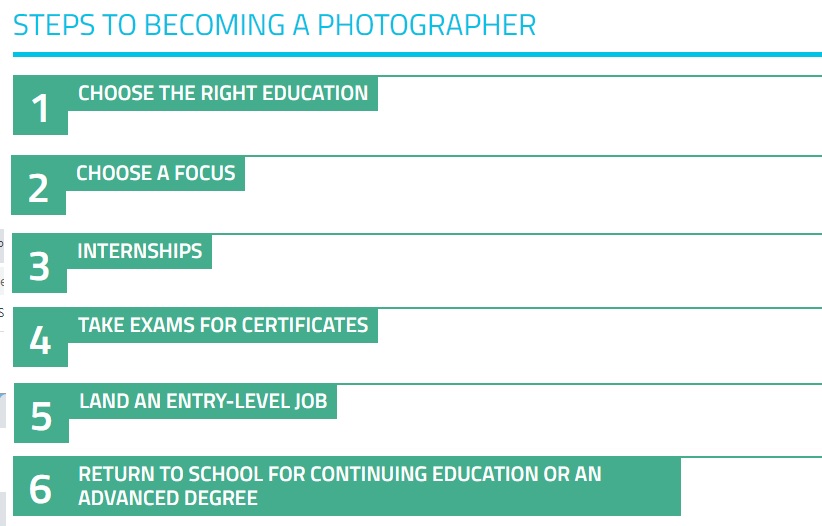

Key Components of Cold Chain Management

Several crucial elements are necessary for effective cold chain management:

- Temperature Monitoring: It is important to maintain constant temperature monitoring to guarantee that the items stay within the designated temperature range. Throughout the supply chain, temperature sensors and monitoring systems are used in this.

- Cold Storage Facilities: Climate-sensitive goods must be kept in specialised cold storage facilities, such as refrigerated warehouses and containers. To maintain the necessary conditions, these facilities are outfitted with temperature-controlled equipment.

- Transportation: Cold chain transportation uses chilled packaging, containers, and vehicles to keep the intended temperature constant while en route. Vehicles with temperature control are necessary for both long- and short-distance travel.

- Packaging: Products sensitive to temperature changes must be packaged in insulated, temperature-controlled environments. It’s essential to package products properly to preserve their integrity.

- Training and Compliance: Employees engaged in cold chain management must complete training on managing items sensitive to temperature changes and adhering to relevant laws. This entails being aware of emergency protocols and temperature monitoring devices.

Supply Chain Management Certification in Cold Chain

A supply chain management certification emphasising cold chain logistics might benefit professionals specialising in cold chain management. These certificates provide the in-depth expertise needed to efficiently manage temperature-sensitive supply networks. They go through things like risk management, temperature control, following rules, and cold chain management best practices.

Conclusion

A vital part of supply chain management, cold chain management ensures that goods sensitive to temperature are transported and stored securely and dependably. Food, medications, vaccines, and biologics are just a few examples of items whose safety and effectiveness depend on their quality and integrity being maintained. Effective cold chain management is essential for cost-effectiveness, customer trust, regulatory compliance, and product quality. Pursuing a supply chain management certification focusing on cold chain logistics may be a beneficial first step for individuals who want to specialise in this industry to get the abilities and information required to succeed in this particular area of supply chain management.